Speed Six General Information

The work that we

have done with the TVR Speed 6 and its derivatives has been exciting,

challenging and technically rewarding, in that we achieved all that we

set out to do (and more....) with our design upgrades, as regards both

enhancing these engines' reliability and their performance.

We therefore invite you to browse through the dyno records,

engineering blueprints and build photos. so as to get a flavour of both the automotive engineering and the industry knowledge

that was needed to create such a world-class series of performance upgrades.

The same expertise, incidentally, that underpinned - and still underpins - the work we undertake on the

American V8 and Ford V6 families of engines, and which you can read about elsewhere on this website.

Contents -

1. Torsional

Vibration and the

Speed Six Engine

One

of the problems with the Speed Six engine is torsional vibration, The

crankshaft is 660mm long from the rear main bearing to the front main

bearing, and the nose is another 127mm on top of that. Total

length is 787mm. This makes for a long crank - 31 inches - in real

money!

Now looking at the two engines, the 3.6 has a stroke of

83mm - or 3.268 inches - and the 4.0 has a stroke of 92 mm - or 3.622

inches. Both engines suffer from torsional vibration, the 4.0 litre

more than the 3.6 because of the longer stroke .

The cause of

this is the rotational mass of crank rods and pistons, which is in two

parts: the crank and the bottom half of the rod (big end) is the

rotating mass, and the top half of the rod small end and piston being a

reciprocating mass.

For

an example of what can happen when things get out of hand, see the

pictures below. Here, a 4.0 litre engine was run up to 7500

rpm

on a dynamometer, and then the throttle butterflies inadavertendly

snapped

shut by the operator..... exactly what happens should you miss a gear

on a downchange.

Little

end showing weak point in rod where breakage occurred.

Damaged

components laid out for inspection.

The rod - or what's left of it, after being dug out from the crank

journal

The cylinders are in pairs 120

degrees apart

and are firing as 1 & 6, 2 & 5 and then 3

& 4. As

each pair reach tdc one cylinder will be exhausting, then once over tdc

it will be on induction, whilst the other will still be on compression,

followed by its power stroke once over tdc. On one 360

degree rotation

of the crank each pair of cylinders will go through the above

cycle.

At the bottom end, the Speed Six's main bearing caps are however only

retained by two nuts and studs with locator dowels.

If

you ever have a chance to look at the main bearings from a disassembled

engine, you will see that there are marks on the outer edges These are

caused by the crankshaft moving and twisting under load,

where

the caps move under the torsional stresses of crank shaft rotation at

each pulse of an individual cylinder's compression/ power stroke, plus

the 'braking' effect on the crankshaft by other cylinders on their

exhaust / induction strokes.

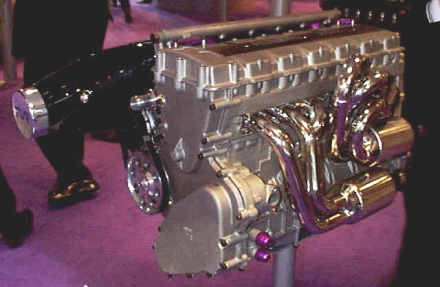

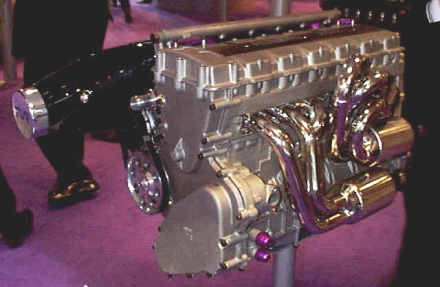

Early

TVR Speed Six re-designed

engine without crankshaft damper:

To try to counteract this

'twisting', TVR followed standard automotive design practice by fitting

a fluid damper to the front of the engine, (actually a small block

chevy part). However, we are still of the opinion that the standard

bottom end remains a weak point of this engine.

Accordingly,

we have developed a revised main cap support modification, comprising

add-on bracing components installed with additional machining so as to

positively locate the caps in horizontal as well as vertical planes.

This both cuts down vibration and strengthens the block in this

critical area at the same time.

2. Boring

and Stroking - how big

can you go?

Whether

it is a Speed 6 or a Briggs and Stratton 4-stroke on a

ride-on

mower - there are only three ways you can increase the capacity of an

engine. By

over-boring the cylinders and fitting matching larger pistons. Using a longer stroke crankshaft

to increase the distance the piston has to travel along the cylinder

bore. By a

combination of both of these.

However,

there are a number of

things you should know before going down any of these routes to gaining

greater power.

To start with, if you

are just overboring your engine, providing there is enough

bore wall thickness to fit the bigger pistons and you have a gasket to

for the larger bore, you will need to adjust ignition and fueling.

If your over bore is over 1mm or .040" thou., how much extra capacity

you will get depends on how long a stroke you have. You can check this

out by using the following formula -

Bore x bore x 0.7854 x

stroke x number of cylinders = capacity

To convert mm to inches

divide by 25.4.

To convert Inches to mm

x 25.4.

When

stroking an engine you have to take into account the following factors: stroke length, rod length, and

piston pin height. The first step after fitting

your

stroker crankshaft is therefore to check the position of the

piston at top dead centre - or T.D.C., as it is known. If you stick with a standard

piston and rod, you will find that the piston will stick out the top of

the block -

so you will need to either machine the piston (only if there is enough

crown thickness to skim it down enough

to give you the correct

compression ratio or valve clearances) or else:

Fit new pistons

with the correct pin height for the new stroke

Use a shorter conrod to

bring the piston down the bore

Do both of the above

Remember, if

the stroke is increased by say

11.8mm or 0.300" thou, you will only need to move the

piston pin nearer the crown by HALF

the extra stroke.

Alternatively, you would shorten the rod by 2.95mm

or 0.150" - or use a

combination

of these two methods to get the compression ratio you need. Now,

by increasing the stroke we also increase piston speed for a

given RPM - because the piston now needs to travel a longer distance,

but in the same time.

Here's an

example. Using the formula -

Piston

speed = stroke in inches

x rpm divide by 6

- we apply this

to an F1

engine with a 40.64mm or 1.6" stroke, which gives

us -

Stroke

of 1.6 inches

x 18000 rpm

Divide by 6 = 4800 ft per minute

Divide by 60 = 80 ft per second (or if you want that in metric, divide

by .3048 = 24.38

meters per second)

These engines

use some pretty exotic materials to

run at these speeds - which

interestingly enough, would also be needed if you increased

the stroke to 3.2 inches but

halved the rpm, since the piston speed would in fact

remain

the same. Though the rpms may have now dropped to 9000, the

inertia shock loads each time the piston reverses direction at the end

of its stroke, plus the need to cope with and dissipate heat that is

built up within the engine through friction and combustion, will

require similar engineering solutions, if the motor is to stay

together.

Talking of friction and

heat, lets turn for a moment and look at rod ratios.

The maths is simple enough -

simply divide

the stroke into the rod length, measured centre to centre from little

end to big end (crank to piston pin).

So, for a 5.7

inch rod, we divide by 3.75

which gives a rod ratio of 1.52.

Which

In our opinion, is just the right side of acceptable. Why? Because once

you go below a ratio of 1.5, the following sorts of issues can all

start to raise their heads -

Side

thrust on the piston is

increased because the rod angle is more acute, leading to

increased wear on the

rings and bores.

Since the piston speed

is faster at top dead centre, cylinder filling is compromised on

overlap.

The pistons can be noisy

- not an issue on a race car, but perhaps a bit wearing on the road.

How does the

TVR Speed Six compare with all this theory? Here are the

factory specifications -

3.6 litre

conrod length is 150mm, with a stroke of 83mm, giving us a rod ratio of

1.8

4.0 litre conrod length is 144.5mm, with a stroke 92mm, yileding a rod

ratio of1.57

For the record, the early 4.0 litre had a shorter conrod, at 142mm long, with a rod ratio of 1.54.

NOTE.

Elsewhere on this site you should find the

technical information on the conrods.

3. TVR

Speed Six

Oil System Upgrade

First

we need to understand the system we have at the moment. The oil is fed

from the header tank to the oil pump, then from the oil pump to the oil

filter on the inlet side of the block through the filter to the main

oil gallery that runs along the inlet side of the block. From the main

oil gallery the oil is then fed to the 7 main bearings to lubricate the

crankshaft, and finally through the crankshaft itself to the big ends.

If

you look at the main bearings you will see one half has an

oil

groove in the part that fits in the block the other half that fits in

the main cap is plain. This means that in the standard engine, as the

crankshaft rotates, oil feeding the big ends is cut off for 180 degrees

of crankshaft rotation. To improve the oil flow, the main caps can be

modified by fitting a grooved bearing in the cap - this allows a

constant oil feed to the big ends and aids cooling as well lubrication.

Turning

to the oiling system in the cylinder head, the oil travels

from

the main gallery up the two oil feeds to the cylinder head on the inlet

side, then goes through the follower shaft on the inlet side

to

the back of the head and stops. The oil also flows forward to the front

of the head, where it crosses over and travels back down the

follower shaft on the exhaust side. This means that the last

part

of the head to get oil is the back of the head. Along the way, the

follower shaft feeds oil to followers and sprays oil on the

camshaft lobes, as well as lubricating the camshaft bearings.

If

you look at each follower, you will see that there is no oil groove in

the centre - so as the follower moves off centre the oil is cut off

momentarily which compromises not only lubrication but the effects of

oil spray cooling to the inside surfaces of the cylinder head.

Additional

oil feed to rear of head, as fitted by RND Engineering to its Speed

Six

heads

To

rectify this, RND fit an additional oil feed to the rear of the head on

the exhaust side. When we first looked at this in 2005, we spoke to Al

Melling direct and his suggestion was to up the oil pressure as well,

which goes along way to rectifying the oil feeds that were removed by

TVR in their redesign. Using Al Melling's original design of

finger followers - which are are not only lighter but are the correct

shape to follow the camshaft - which now have a 360 degree

oil

groove added, constant oil flow to the camshaft lobe is

achieved,

and cooling to the cylinder head enhanced . We have redesigned the oil

pump its an all new pump with stronger main shaft and deeper rotors to

increase oil flow by 30% and also increases oil pressure by doing all

this we go along way to getting things back to the original design. To

get things even closer to the 'what should have been' engine

specification, you can fit our Al Melling designed valves with 8mm

diameter valve stems and reduced pressure valve springs.

To

summarise these changes, we now have a new oil feed to the back of the

head, 360 degree oiling to the mains and big end bearingss, and

redesigned finger followers

with 360 degree oiling and constant flow of oil to the camshaft lobes.

All this aids cooling, as well as ensuring oil is always present where

and when it is needed.